A local Danish district heating company, Silkeborg Forsyning, established a thermonet solution for 15 houses in 2017-18, including 14 newly built houses.

Heat is extracted via shallow vertical geothermal boreholes. The thermonet itself and heat pumps in the connected houses were established as a demonstration project with support from Region Midtjylland’s development program FjernvarmeVækst. Houses were connected progressively as construction was completed, and the system came into full operation in 2018..

The district heating company owns the geothermal boreholes, the thermonet, and the heat pumps. The project aimed to provide residents with affordable collective heat supply comparable to conventional district heating, which is typically not economically viable in small towns.

The project was based on an R&D study from 2017, which compared the economics of a thermonet solution with conventional district heating, individual shallow geothermal heat pump systems, and individual air-to-water heat pumps.

Actors

Silkeborg Forsyning is the facility owner and financed the investments. Homeowners became customers of Silkeborg Forsyning and are billed as if they were conventional district heating customers.

The project received support for project management and development from Region Midtjylland’s pool FjernvarmeVækst, which was administered by the Danish District Heating Association’s think tank Grøn Energi. PlanEnergi was the project manager.

Klimadan established the thermonet and supplied and installed the heat pumps. Kamstrup supplied the energy meters. The heat pumps are manufactured by the Swedish heat pump manufacturer Thermia.

GeoDrilling was responsible for establishing the geothermal boreholes with Varup Termiske Boringer as the executing drilling contractor and with Dantonit as supplier of the grouting material for the boreholes.

Under the auspices of Lund University, a digital twin was built after the system’s commissioning and analysis of its performance and electricity consumption was conducted.

The solution

15 houses are connected to the thermonet (14 new houses and 1 existing house).

Six shallow geothermal boreholes of 120 meters depth are connected to a collection chamber for the main pipes. The thermonet consists of a total of 484 meters of uninsulated plastic pipes. The average supply temperature for extracted geothermal heat is 8°C. A chamber has been established for an expansion tank for the entire system.

In the houses, heat pumps are installed in the location where district heating units would be placed in a conventional district heating system. The heat pumps in the 14 new houses are of the type Thermia Diplomat Optimum G3 with 6 kW heat output. In the existing house, the heat pump is of the same type, but with 10 kW heat output.

Heat consumption is billed for each house based on two Kamstrup heat meters: one for space heating and one for domestic hot water. Additional electricity meter for the heat pumps have been installed in each house.

Based on meter data, Silkeborg Forsyning can continuously calculate the heat pumps’ COP values. Operational monitoring is done using the Thermia Online system. Heat is priced at the level of conventional district heating delivered by Silkeborg Forsyning to other customers.

Economics

The total cost for establishing the thermonet and six vertical shallow geothermal boreholes was DKK 871,000 (2018 prices). The choice of an interface directly comparable to conventional district heating raised total costs of the thermonet solution. Customers pay the same heating tariff as conventional district heating customers.

Thermonet maximizes utilization of shallow geothermal boreholes

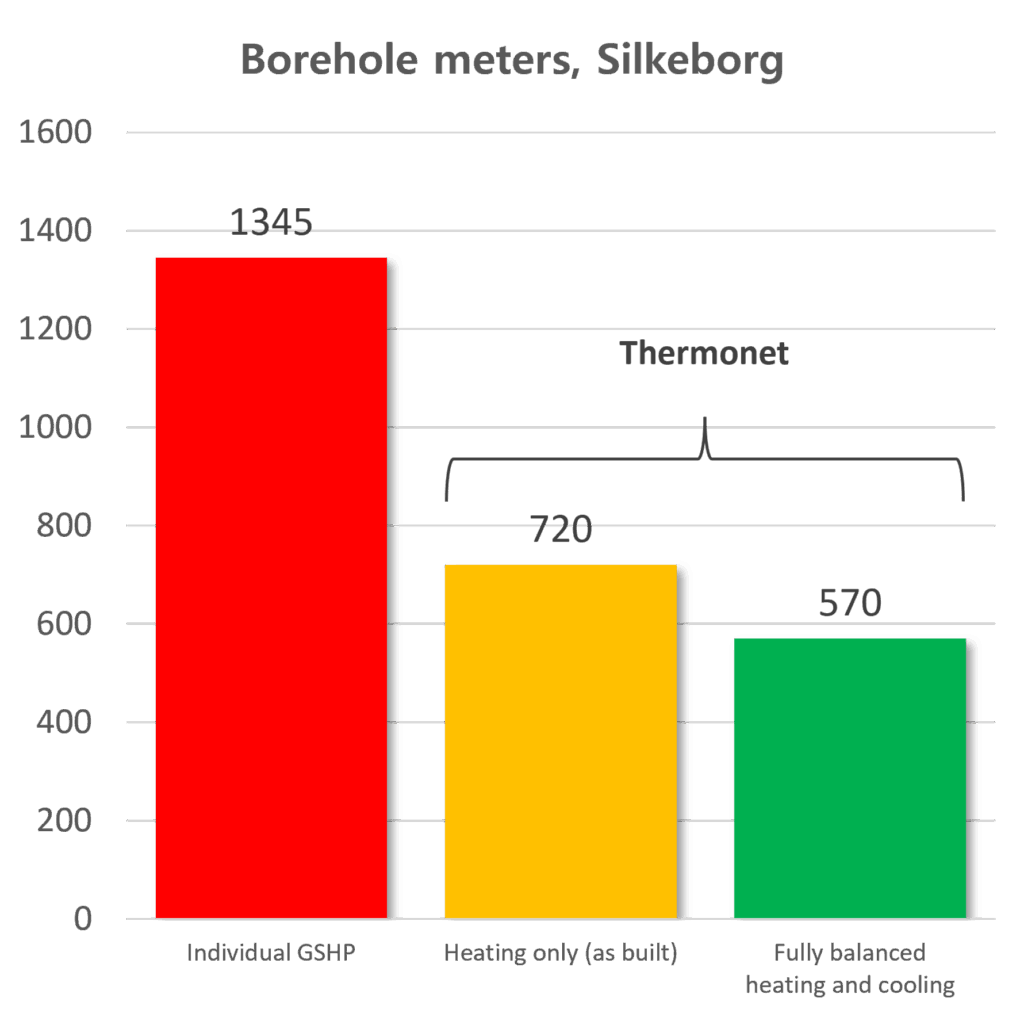

Calculations conducted by Associate Professor Ph.D. Søren Erbs at VIA University College show that the thermonet (with a total pipe length of 484 meters) has reduced the need for the relatively expensive vertical geothermal boreholes.

If each house had an individual geothermal system, 15 boreholes would be required. With the thermonet solution in Silkeborg, only 6 boreholes were needed. If the system had been established to deliver both heating in winter and passive cooling in summer, 4 or 5 boreholes would have been sufficient.

An analysis conducted by Marwan Abugabbara as part of his PhD dissertation at Lund University shows that up to 20 percent of the delivered heat is extracted via the thermonet pipes themselves. This analysis demonstrates that a thermonet extracts heat from the surrounding ground, contrasting with conventional district heating where distribution at higher temperatures inevitably causes heat loss.

Continued potential for optimization

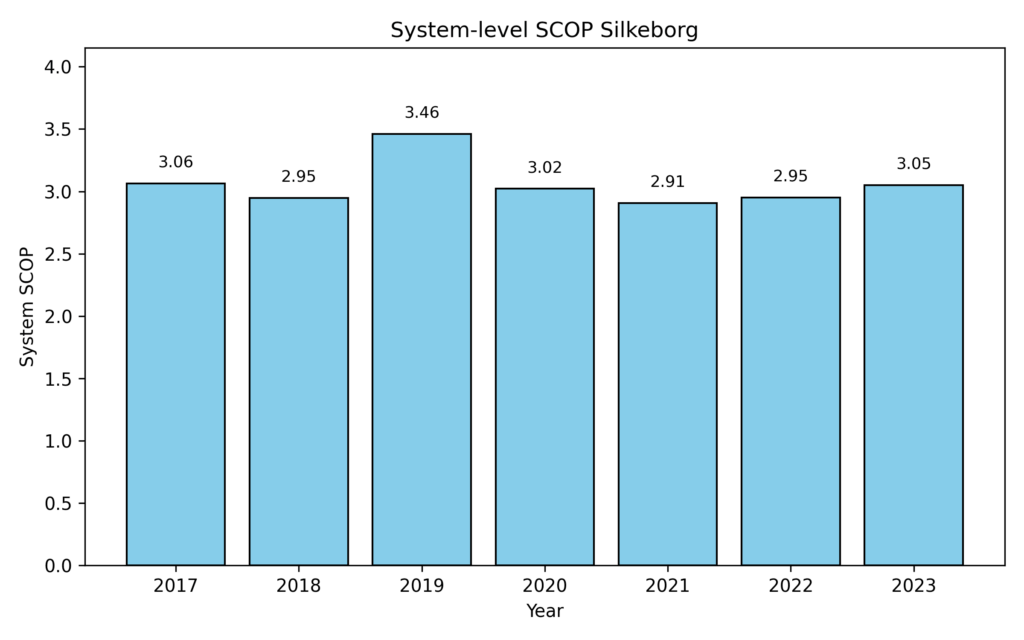

As part of an ongoing research project (2024-), operational data has been collected and SCOP values for the thermonet have been calculated for the period 2017-2023. These are shown in the following diagram:

For a system of this type, expected SCOP values are typically 3.5-4.0, and the system’s efficiency (Carnot efficiency) could likely be improved. Efficiency becomes low, for example, if the electric heating elements in the houses’ hot water tanks are used frequently. This underscores the importance of properly commissioning and adjusting heat pumps for optimal operation when establishing a thermonet.

Key experiences

- The thermonet’s supply and return pipes were laid with 1 meter spacing, which required wide trenches and consequently increased excavation costs. It is possible instead to lay the pipes with as little as 30 cm spacing, which reduces excavation costs.

- The operational monitoring of the system gives customers security, and it can be an advantage in operation and communication with customers that the heat pumps are owned by the district heating company. From a cost perspective, alternative ownership models could be considered, where the utility company is responsible only for heat extraction and the thermonet, while consumers own their individual heat pumps and pay for the associated electricity consumption.

- The installation of many meters in individual households is costly. If it is possible instead to use sub-meters for electricity or to measure heat consumption on the cold side of the heat pumps, meter costs can be reduced.

- The thermonet enables energy-efficient passive cooling in summer. Modifying one house in Silkeborg to demonstrate this cooling capability has been considered but not yet implemented. Similar energy-efficient passive cooling is not possible with individual air-to-water heat pumps.

Further information

- R&D project, which was the predecessor to the “Kold Fjernvarme” project:

https://danskfjernvarme.dk/viden-vaerktoejer/udgivelser/kold-fjernvarme - Final report on the demonstration project supported by Region Midtjylland’s Fjernvarmevækst: https://www.danskfjernvarme.dk/-/media/danskfjernvarme/gronenergi/projekter/kold-fjernvarme-slutrapport.pdf

- The thermonet in Silkeborg was included as a case study in a PhD dissertation written by Marwan Abugabbara at Lund University in 2023, read the case here (pdf page 78-79, printed page 50-51)

- Pythermonet dimensioning tool for thermonet is described in an article by researchers Søren Erbs Poulsen and Karl Tordrup: An integrated design model for ambient temperature district heating and cooling networks.