Denmark’s largest thermonet to date was commissioned in late 2024 in the residential development of Hyllegaard Høje near Hvalsø on Zealand. It is designed to supply heating to 200 homes.

The thermonet was installed as part of site development and is supplied by horizontal geothermal heat extraction. This consists of approximately 30 km of plastic pipes ploughed into the ground in two separate sections, covering a total of roughly 3 hectares of agricultural land.

The residential development comprises six cohousing communities, which are being connected to the thermonet as they are constructed and occupied. In late 2024, residents moved into the first community, Sjællandsk Muld. Two further cohousing communities are under development and are expected to be ready for occupancy in 2027–2028. The plan is for all six cohousing communities to be completed by 2035.

The planned development covers a total of approximately 11 hectares, with an additional 11 hectares of collectively owned farmland. The area is being developed by Hyllegaard Udvikling ApS (HUA). The developer chose to install the full geothermal heat extraction system for the thermonet from the outset, as the farmland will be planted and cultivated.

The main distribution pipes of the thermonet have been constructed with seven interface chambers with valves, allowing each cohousing community to be connected to the system as it becomes operational.

Design requirements ensure energy efficiency

HUA is selling the six building plots to developers one at a time. Each developer is legally obliged to comply with a design manual and accompanying guidelines provided by HUA and to pay a connection fee to the local co-owned energy community serving the development. Additionally, developers must register that all plot and house owners are members of the local energy community.

HUA has drawn up the design manual to ensure the overall development is as sustainable and energy‑efficient as possible. Key requirements for heating and, where applicable, cooling include:

- Heating must be provided by ground source heat pumps connected to the area’s thermonet and its shared geothermal heat extraction system.

- Each cohousing developer must engage in dialogue with HUA regarding connection to the thermonet to identify the most technically suitable solution.

- Electricity and heat meters must be installed with each heat pump to record operational data, enabling the local energy community to optimise system performance.

- The local energy community is responsible for operating the thermonet and managing local electricity generation from rooftop solar panels.

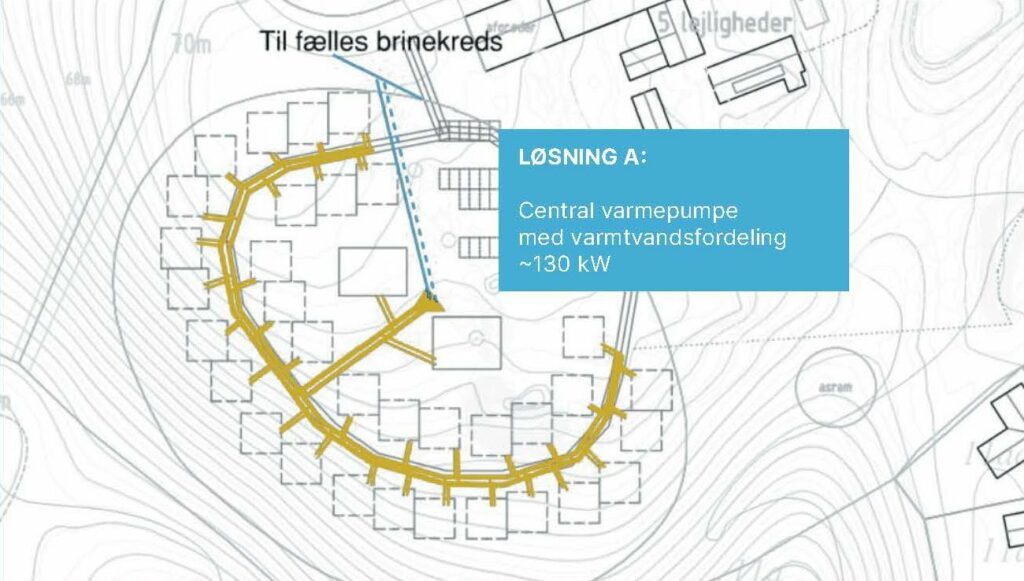

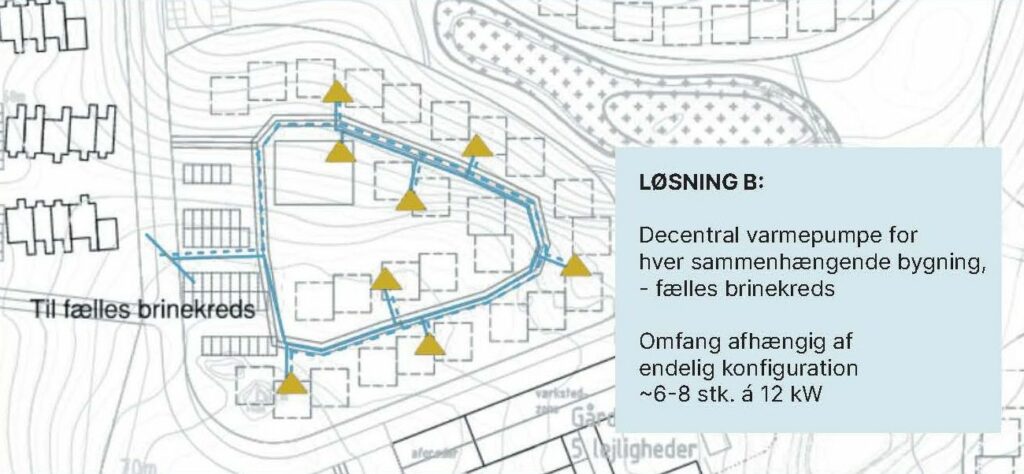

HUA outlines two possible technical configurations for shared heating and optional cooling systems:

A. Installation of a single large heat pump per cohousing cluster, housed in a separate technical shed. Heat is to be distributed from the heat pump to the homes as low‑temperature district heating through insulated pipes with a flow temperature of 45 °C and a return temperature of 30 °C suitable for underfloor heating. In this setup, domestic hot water must be additionally heated in each dwelling using tanks with electric heating elements or a small domestic water heat pumps (boosters).

B. Installation of decentralised heat pumps in each building (typically 3–6 homes) with a shared technical shed per building. In this design, it is up to the developer to determine how domestic hot water will be supplied to each dwelling.

In both options, developers may choose to install passive cooling for summer use via heat exchangers in ventilation systems.

Heat Pumps are powered by onsite solar electricity

Regardless of the chosen system configuration, the heat pumps are to be powered as far as possible by electricity from a large photovoltaic array installed on the roof of the community centre. Both the solar PV system and the distributed heat pumps form part of the integrated heating system owned by the local energy community.

This arrangement allows electricity to be shared between buildings for use in heat pumps without incurring grid tariffs and energy taxes – a practice that is otherwise not permitted under current Danish regulations. It becomes legally possible because the heat pumps are placed in shared technical buildings separate from the individual homes, making them formally part of a communal thermal supply system. If solution B is used, the technical sheds must be physically attached to the buildings they serve but – due to the current Danish regulations – have their own official building registration numbers (BBR).

Based on HUA’s plan, developers must also install solar PV systems on the rooftops of residential buildings for general household electricity needs. This electricity can likewise be shared internally within each building free of tax on electricity and free of tariff for use of the collective grid. However, electricity from rooftop systems may not be used tax‑free to power heat pumps within the same building due to current Danish regulations.

The only reason for the described metering and ownership structure for electricity production and consumption is the existing Danish regulations. Likewise, the inability to combine or balance electricity generation and usage across buildings and the thermonet is regulatory rather than technical. A shared local energy system with common electricity generation and potentially also local battery storage would have been more energy‑efficient, required fewer installations, and reduced administrative complexity.

According to the sales agreement, each cohousing developer must transfer ownership of the completed heating and the optional cooling systems to the co-owned local energy community.

35 Homes supplied by nine decentralised heat pumps in the first community

The first cohousing community, Sjællandsk Muld, was developed by the housing association Almenr, which opted for solution B – decentralised heat pumps installed in each building. Sjællandsk Muld consists of nine buildings, each with 3–5 homes, totalling 35 homes. In addition, there are three self‑build houses, each with its own heat pump connected to the thermonet.

Each of the nine buildings has an adjacent technical shed housing a frequency‑controlled 6 kW Klimadan heat pump with a peak output of up to 10 kW. From the heat pump, space heating is distributed to each home in a separate circuit, and each dwelling has individual room thermostats.

The nine technical sheds have been built on their own foundations to ensure they qualify as part of the communal heating supply and to minimise any potential noise nuisance from the geothermal heat pumps. No cooling system has been installed in the Sjællandsk Muld cluster.

Design of the heat extraction and thermonet System

The 30 km of pipes used for geothermal heat extraction are 40 mm in diameter and laid with 120–130 cm spacing. As the land is to be cultivated, partly using permaculture methods, the pipes have been ploughed in at a depth of 120 cm using a specialised plough.

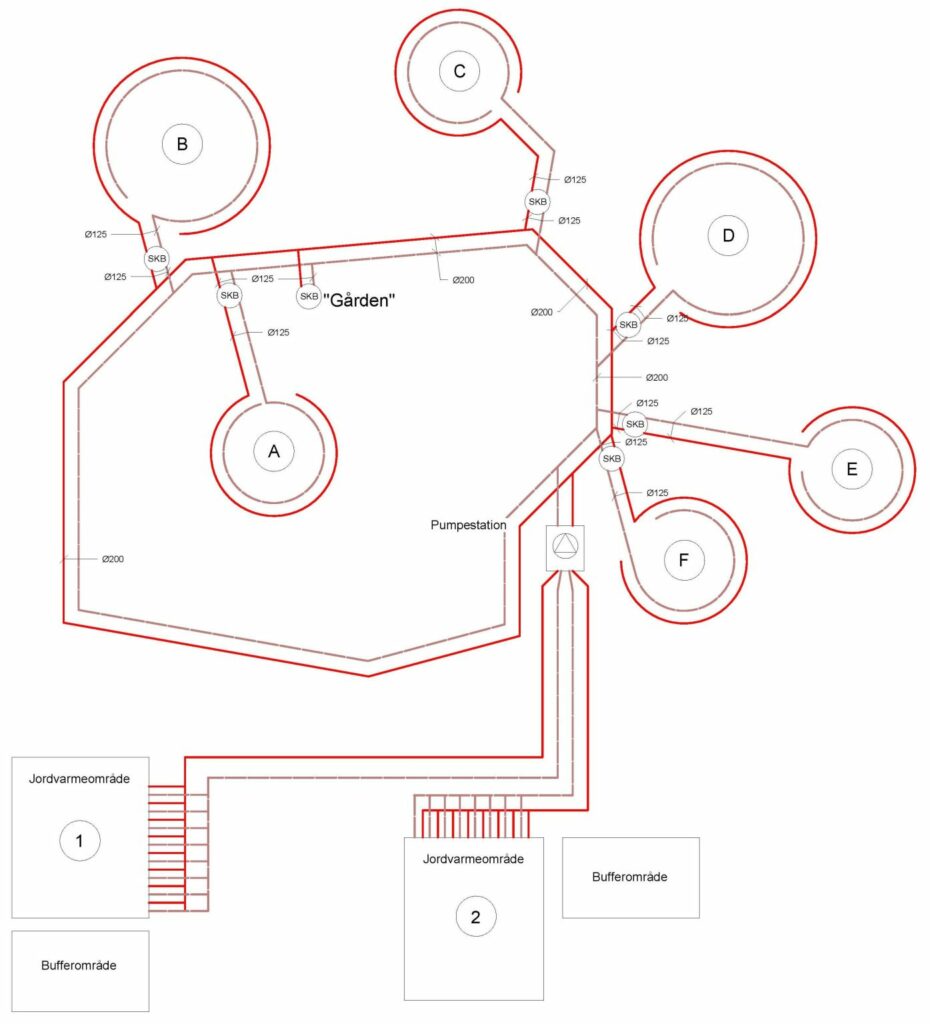

Below you can see how the thermonet is structured. The distance between cohousing community B and the pump station is not very long, and this is only a schematic diagram.

See a more detailed and precise drawing from SWECO, showing Hyllegaard Høje’s thermonet as built.

The thermonet’s main pipes have a diameter of 200 mm. A central pump station has been installed between the heat extraction area and the residential development. The pump station is redundant relative to the pumps in the distributed heat pumps but ensures maximum system reliability. The station also allows each of the two geothermal heat extraction zones to be disconnected for maintenance.

Each cohousing cluster has its own interface chamber with valves. The distribution pipe from each interface chamber has a diameter of 125 mm. During short periods, such as maintenance, a cohousing cluster’s heat pumps can operate using only the thermal energy stored in the section of the thermonet located downstream of its interface chamber.

The thermonet and shared electricity production are operated by the local energy community, Hyllegaard Høje Energifællesskab AMBA. The energy community has signed a service agreement with Klimadan and an administrative agreement with EBO Consult.

Project Partners

Hyllegaard Udvikling ApS (HUA) is the project developer.

Kuben Management is the developer’s consultant and contracting authority for the thermonet.

Ulrik Jørgensen was consultant to HUA on energy community and thermonet/electricity network.

WSP and SWECO are engineering consultants responsible for thermonet design.

Snoldelev Entreprenørfirma was the main contractor for geothermal heat extraction and thermonet, including pump station and interface chambers.

Klimadan supplied and installed heat pumps and pump station equipment.

HUA was responsible for the thermonet section in Sjællandsk Muld.

More Information About the Project

- HUA’s information for developers (in Danish) and design manual (pdf-file, in Danish)

- Guide to establishing energy communities at Hyllegaard Høje (pdf-file, in Danish)

- Guide to shared heating supply (pdf-file, in Danish)

Media Coverage (in Danish)

17. marts 2025, TV2 Kosmopol:

Ny type energifællesskab vinder frem: “Det handler om at sikre en sund planet”

8. juni 2023, Energiforum Danmark:

Fælles jordvarmeanlæg skal give bofællesskab i Hvalsø grøn varme

17. maj 2023, Dagens Byggeri:

30 km termonet trækker CO2’en ud af Danmarks (måske) største bofællesskab